Radial Press Jointing |

Previous Page |

|

:: REMS press tools :: Universal for all common pressfitting systems REMS â radial presses

|

|

:: REMS Eco-Press :: Manual radial press Universal, manual radial press for poducing pipe pressing joints

for all common pressfitting systems. |

|

:: REMS Power-Press E :: Electric radial press Universal, handy electric tool for making pipe pressing joints

for all common pressfitting systems. |

|

:: REMS Power-Press 2000

:: Electric radial press with electronic switch-off Universal, handy electric tool with electronic switch-off for

making pipe pressing joints for all common pressfitting systems. |

|

:: REMS Power-Press ACC :: Electric hydraulic radial press with circuit control Universal, handy electric tool with automatic circuit control for making pipe pressing joints for all common pressfitting systems. Pressing joints à 10â76 (108) mm. REMS pressing tongs, also suited for drive units of other makes. REMS Power-Press ACC â universal up to à 76 (108) mm. Secure crimping in seconds. Automatic circuit control. Automatic locking of pressing tongs. Complete assortment of REMS pressing tongs for all common pressfitting systems. |

|

:: REMS Akku-Press :: Cordless radial press with switch-off signal Universal, handy electric tool with switch-off signal for producing

pipe pressing joints for all common pressfitting systems. No cable.

|

|

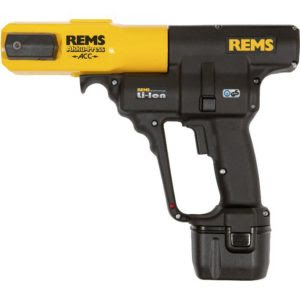

:: REMS Akku-Press ACC :: Cordless radial press with automatic circuit control Universal, handy electric tool with automatic circuit control

for producing pipe pressing joints for all common pressfitting systems.

No cable. |

|

:: REMS pressing tongs :: Accessories for REMS Eco-Press, REMS Power-Press E, REMS Power-Press 2000, REMS Akku-Press, REMS Akku-Press ACC and other makes REMS â high compression pressing tongs in forged and specially

hardened steel |

|

:: Confirmation of suitabilities

:: The suitability of press tools is determined basically

by the manufacturer of press tools. Moreover the suitability of

REMS press tools has been confirmed by the system manufacturer/supplier

himself or approved through independent testing institutes. |

|

:: SHK â Hold-Harmless and

Indemnification Agreement :: A hold-harmless and

indemnification agreement exists |

|

:: REMS cropping tongs M :: Accessories for REMS Eco-Press, REMS Power-Press E, REMS Power-Press 2000, REMS Akku-Press, REMS Akku-Press ACC and other makes High performance cropping tongs in forged and specially hardened

steel for cutting threaded rods. |

|

:: REMS cable shear :: Cable shear High-grade cable shear in forged and specially hardened

steel for cutting electric cable. |

|

||

Radial Press Jointing |

Previous Page |